Gandhi Nagar, Bangalore, Karnataka

- GST NO. : 29JCRPS1544D1Z2

| Business Type | Manufacturer, Importer |

| Certification | CE Certified, CQC Certified, IAF Certified, ISI Certified |

| Weight | 150-200gm, 200-250gm, 250-300gm, 300-350gm |

| Feature | Auto Controller, Dipped In Epoxy Resin, Durable, High Performance, Stable Performance |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

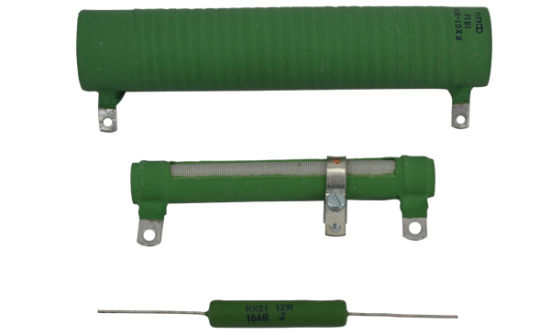

Wire Wound Resistors VALUES RANGING FROM 0.01E TO 100K WWR

Wirewound resistors are commonly made by winding a metal wire, usually nichrome, around a ceramic, plastic, or fiberglass core. The ends of the wire are soldered or welded to two caps or rings, attached to the ends of the core. The assembly is protected with a layer of paint, molded plastic, or an enamel

We are reckoned as one of the prominent traders of Wire Wound Resistors. Our wirewound resistors are manufactured using best available raw materials that are procured from some well established vendors. These resistors find applications in Electronics, Automation, Medical, Conveying industries and many more. Our resistors are known for the features like superior design, high performance and long service life. We offer our resistors in different design specifications to cater the broad demands of the industry.

Key uses

- Electronics companies

- Electrical companies

- Material handling companies

- Automation companies

Features

- Wire wound resistors custom built in adjustable style with presentable bands.

- Varnish coated

- Resistance wire

- Copper nickel alloy for low and medium values

- Nickel chromium alloy for high values

- Coating glossy varnish, class f, grey colour

- Leads - radial,copper wires,solder plated.

- Construction - tubular with central hole stud insert molded plastic end capsTolerance +/- 10% +/- 5%.

- Breakdown voltage >= 500v (b/w leads & body)

- Temperature coefficient - better than + 150 ppm / deg. C.

- Temperature severity - 40c to + 200c

- Endurance - change in value < 3% after 1000 hours at 70c, full load

- Humidity - change in value < 1. 5% after 1000 hours at 40c, 90-95% rh

- Long functional life

- Highly efficient Specifications:

- High Grade Ni- Cr wire Wound element

- Coated with heat insulating Flame Proof coating

- High surge with standing suitable for energy meters

- Low Temp-Coefficient, High stability

- Color Coded or Printed ensured low inductance

- Ayrton-Perry winding ensured low inductance

- Standard tolerance 1%, 2%, 5% available

Applications

- Applications where online selection of resistance value is required

- As voltage dividers

- As multi-tap resistors

Technical Specification

|

Watts |

W (mm) |

H (mm) |

L (mm) |

|

1 |

6 |

6 |

16 |

|

2/2.5/3 |

7 |

7 |

16 |

|

4 |

7 |

7 |

20 |

|

5/6 |

9 |

9 |

25 |

|

7 |

9.5 |

9.5 |

32 |

|

9/10 |

9 |

9 |

38 |

|

12 |

11 |

11 |

38 |

|

15 |

9 |

9 |

45 |

|

20 |

9 |

9 |

52 |

|

25/30 |

11 |

11 |

55 |

|

40/50 |

11 |

11 |

65 |

|

75 |

11 |

11 |

85 |

|

100 |

11 |

11 |

100 |

Looking for "Wire Wound Resistors" ?

Explore More Products