Gandhi Nagar, Bangalore, Karnataka

- GST NO. : 29JCRPS1544D1Z2

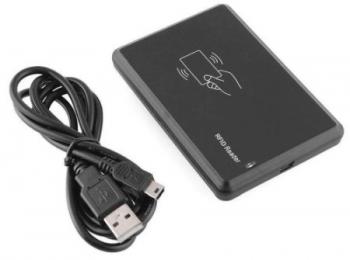

Readers

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of RFID Card Reader, NFC Reader and Barcode Card Reader from Bangalore.

| Business Type | Manufacturer, Importer |

| Power Input | USB from PC |

| Interface | USB, 106bit/s, no extra driver is need |

| Working Distance | Up to 8cm |

| Frequency | 125KHz |

| Operation Temperature | -30°C to +60°C |

Preferred Buyer From

| Location | Worldwide |

Advantages :

- Handy reader

- Easy to interface

- More Data Security

- Adaptable and convenient

Applications :

- Applications that need to protect personal data and deliver fast and secure transactions such as transit fare payment cards, financial payment cards.

- Applications that need to save like government and corporate identification cards, documents such as electronic passports and visas.

| Business Type | Manufacturer, Importer |

| Warranty | No Warranty |

| Product Code | REA00014 |

Preferred Buyer From

| Location | Worldwide |

FEATURES :

- CCID Compliance

- USB 2.0 Full Speed Interface

- Smart Card Reader read/write speed up to 424 kbps

- Built-in anti-collision feature (only 1 tag is accessed at any time)

- Built-in antenna for contactless tag access, with card reading distance of up to 50 mm (depending on tag type)

- Supports ISO 14443 Type A and B cards, Mifare, FeliCa, and all 4 types of NFC (ISO/IEC 18092) tags

- Application Programming Interface Supports PC/SC and CT-API (through wrapper on top of PC/SC)

- Peripherals User-controllable bi-color LED and User-controllable buzzer

| Business Type | Manufacturer, Importer |

| Warranty | No Warranty |

Preferred Buyer From

| Location | Worldwide |

Advantages :

- Barcode systems provide an array of benefits, including operational efficiency, better customer service, and improved visibility of key business information to management.

- Speed : A bar code label of twelve characters can be winded in approximately the time it takes a keyboard operator to make two keystrokes.

- Accuracy : For every 1,000 characters typed by a keyboard operator, there are an average of ten keying errors. For an Optical Character Reader (OCR), there is one error in every 10,000 reads. With wands, barcode systems approach one error in every 3,000,000 characters, and with laser technology, they approach one error in 70 million entries.

- Ease of Implementation : Operators of bar code scanners can learn to use the equipment effectively in less than 15 minutes. System costs are lower than other means of data entry because of the existence of interfacing hardware and software. Barcode labels can cost less than a penny apiece, are easily read by thousands of commonly available devices, and can be printed universally.

- Cost Effectiveness : Barcode systems have a demonstrated payback period of six to eighteen months, and they provide the highest level of reliability in a wide variety of data collection applications. Barcode systems create value not only by saving time, but also by preventing costly errors.

Application :

- Bar codes can be used in every business around the world. For example:

- Consumer tracking from the retailer perspective (for example, loyalty card programs that track consumers purchases at the point of sale by having them scan a Barcode).

- To track assets in any building including every desk, computer, telephone, copier and desk accessory.

- To track mail from the time it arrives in the mail room to the time it is delivered to each desk or location within an office.

- To help security guards identify every employee, every door they enter and every room they work in.

- To secure, lock or unlock entrances or exits throughout the plant.

- To manage and track your vehicle fleet and each driver Industrial barcode reader used to identify products during manufacture or logistics.

- Often used on conveyor tracks to identify cartons or pallets which need to be routed to another process or shipping location.

- Used in factory and farm automation for quality management and shipping.